Description

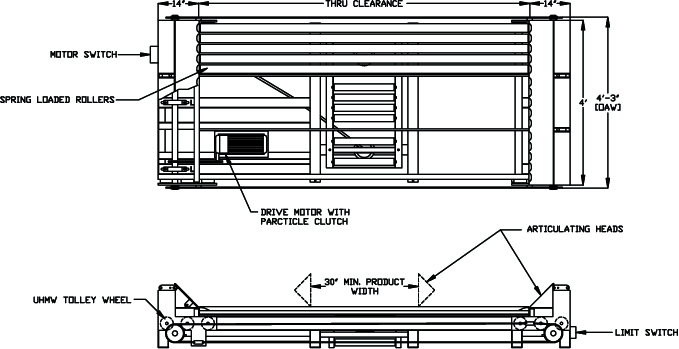

The device also includes “articulating” heads with scalloped edges to ensure contact with the bottom of the load and to “break” or “fold-up” bottom sheets along the sides of the load. This unit is an integral part of a Power Live (PLR) or Power Accumulating (PARC) Roller Conveyor.

Features

Centering Heads

Two (2) 48” wide x 1⁄2” Steel Head Weldments mounted to 4” Dia. Tapered Ultra High Molecular Weight (U.H.M.W.) trolley wheels that ride in a structural channel track.The heads are driven by two#60 Chains connected to a common 11⁄2” dia shaft mounted in precision pillow block bearings.

- Roller Spacing around chain bars is 4-1⁄2”, 3” on all remaining rollers.

- Scalloped Heads are provided which ride below the roller surface to ensure contact with the bottom of product. The Heads include a U.H.M.W. wear strip, which is in contact with the rollers.

- Overall Width only adds 14” to each side of the “Thru Clearance”.

- Optional “Non-Articulating” Heads are available for machine infeeds or pallet applications.

- Optional OEM Controls are available for Stand-Alone units.

Drive

1 HP totally enclosed industrial rated 1750 R.P.M. motor/reducer with magnetic parti- cle clutch. Drive Package located within and under the device.

Optional Feature

Full height (48”) Backstop mounted to Articulating Head for load stability.

Speed

Head speed is a constant 45 F.P.M.

Preassembly

Unit is wired and (if applicable) plumbed to a junction box at the factory. Conveyor Height: 12” TOR minimum with Leg and Device Extensions available for other heights.

Capacity

5,000 lbs. maximum.

Voltage

System Voltage is 460/575 volt, 3 phase, 60 hertz with 115 volt, single phase control voltage.